US-based 3D printer manufacturer 3D Systems has agreed to sell its Geomagic software portfolio to Hexagon’s Manufacturing Intelligence Division. The transaction, worth $123 million, is expected to close in the first half of 2025 following customary regulatory reviews.

This decision follows a strategic review, which will see 3D Systems prioritise the software it deems central to accelerating the adoption of its metal and polymer 3D printing technologies. These platforms include 3D Sprint, 3DXpert, and the Oqton Industrial Manufacturing Operating System. 3D Systems called Oqton integral to the company’s software strategy.

Dr. Jeffrey Graves, president and CEO of 3D Systems, stated that this divestiture leaves the company “well-positioned for the future.” He noted that 3D Systems retains “the broadest technology base in the industry, the scale needed to support our customers in production environments, and a fortified balance sheet to continue driving our industry leading innovation.”

The Geomagic software brand launched in 2013 after 3D System acquired Geomagic Inc. for $55 million in cash. It has since built a strong customer base and is well known for its reverse engineering capabilities. Graves reassured existing Geomagic customers that “Hexagon is an ideal strategic owner” for the Geomagic assets, and that “the future will be bright under their stewardship.” The Stockholm-based manufacturing technology company specializes in metrology, simulation and design.

“The changes we’re announcing today will sharpen our focus on those software platforms that are most critical to our customers’ success in this new-use environment,” added Graves. “By streamlining our software operations, focusing exclusively on our core platforms, and leveraging the exceptional capabilities that AI is now making available to us, we will be better positioned to support our customers’ most critical requirements as they move 3D printing into high-volume production environments.”

3D Systems sells Geomagic amid strategic review

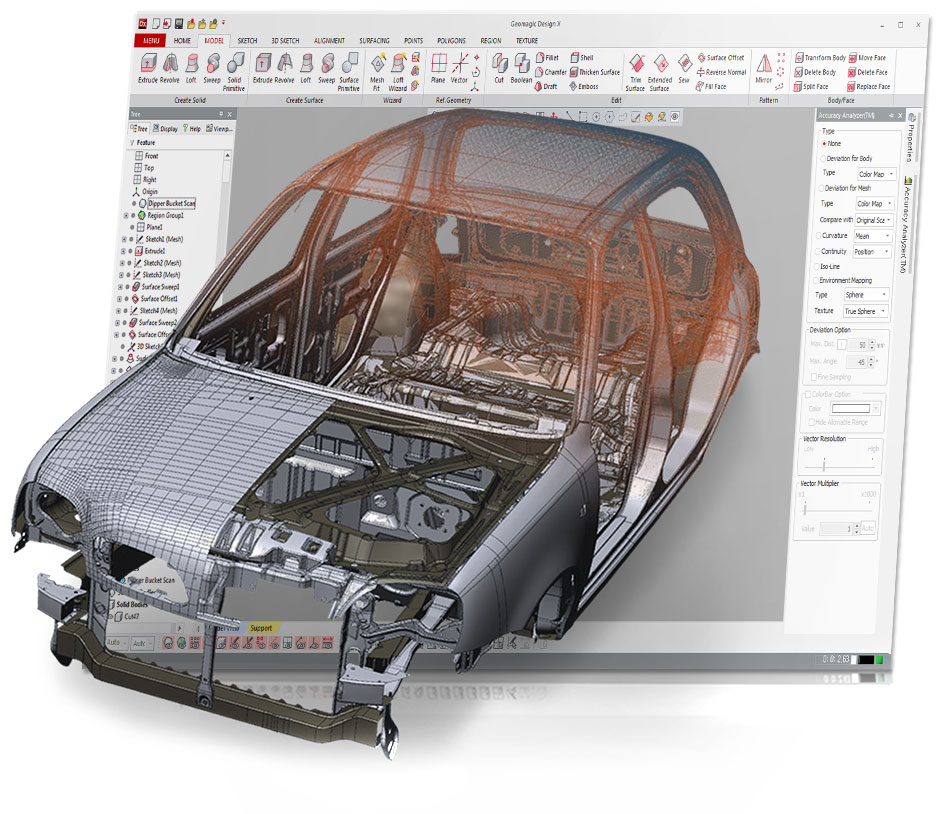

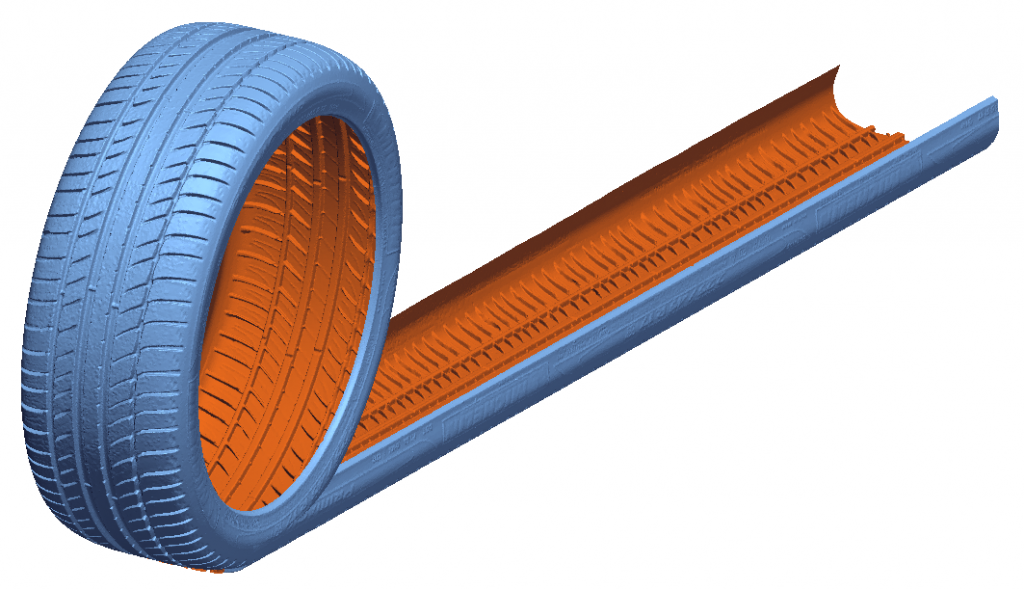

Geomagic is a well-established additive manufacturing software portfolio featuring Geomagic for SolidWorks, Control X, Freeform, Wrap, and Design X. The latter has seen broad adoption within reverse engineering applications, allowing users to create digital CAD models from 3D scan data. Geomagic Freeform facilitates the design of complex and organic models, while Control X offers advanced measurement and inspection capabilities.

3D Systems believes Hexagon is “ideally positioned to harness the power of the Geomagic portfolio to offer a more complete scan-to-CAD workflow, to bridge the physical and digital worlds.”

The South Carolina-based 3D printer OEM will now sharpen its focus on its 3D Sprint, 3DXpert, and Oqton platforms. 3D Systems’ believes these offerings are better positioned to increase the adoption of additive manufacturing in “large-scale, production application environments.”

By committing resources to these platforms, the company believes it will successfully accelerate software development efforts and augment its products to help customers “unlock the full potential of AM.” These efforts will include further development of AI and machine learning (ML) capabilities which 3D Systems views as essential to unlocking high-reliability production.

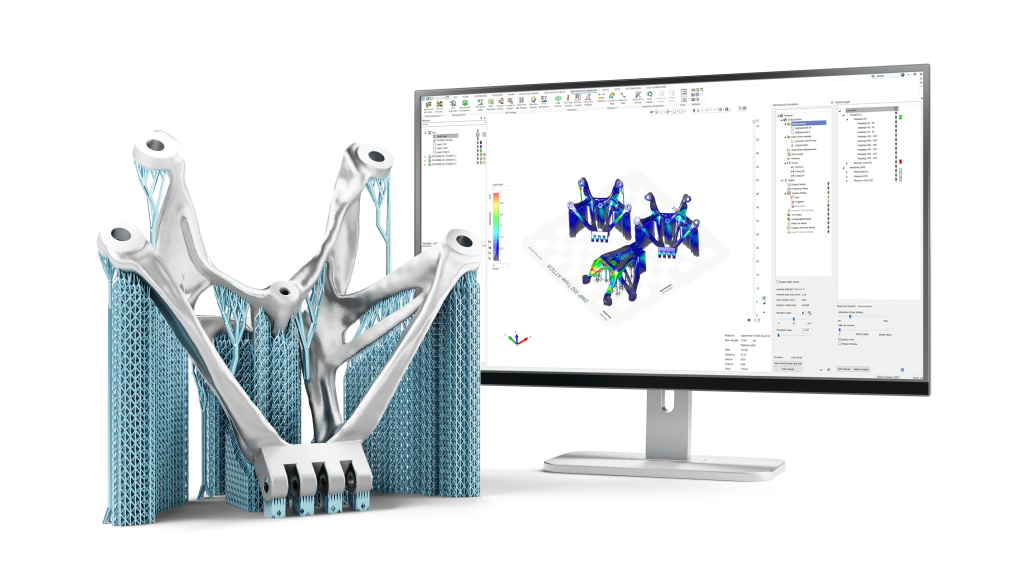

3DXpert and 3D Sprint are critical to 3D Systems’ metal and polymer 3D printing systems. Increasing investment into these platforms will reportedly allow the firm to increase R&D efforts and address the needs of more applications.

3DXpert combines design for additive manufacturing (DfAM), build preparation simulation and inspection to unlock shorter lead times, lower manufacturing costs, and enhance designs. The platform uses AI and ML to automate repetitive design and part inspection tasks.

3D Sprint allows users to prepare and optimize CAD and polygon data while facilitating the management of 3D System’s polymer 3D printers. It supports the design process from file preparation to production in the same workflow. This reportedly helps users avoid errors, saving time and money.

3D Systems’ Oqton Industrial Manufacturing OS (MOS) leverages AI to increase throughput, scale production, and maximize operational efficiency. It can manage, automate, and prepare manufacturing data. The workflow encompasses design, inspection, and certification processes, offering end-to-end traceability and efficiency. One notable adopter of Oqton MOS is Baker Hughes. Earlier this year, it was announced that the energy technology company was using Oqton MOS to optimize and automate additive manufacturing workflows.

Baker Hughes first partnered with 3D Systems in early 2023 to develop an industrial ecosystem that increases efficiency and enables regulatory compliance for energy, aerospace, and healthcare industries. Both companies have been nominated for the 2024 3D Printing Industry Awards for this collaboration, having commercialized a software solution supporting on-demand 3D printing for regulated markets.

3D printing divestitures and strategic re-structuring

3D Systems is the latest additive manufacturing firm to restructure its strategic focus and product offerings. In January 2023, French 3D printer manufacturer and service provider Prodways Group discontinued sales of its wax and resin jewelry 3D printers. The company reallocated resources towards high-volume, industrial 3D printers which it claimed possess higher added value.

This strategic decision followed poor sales results for the Solidscape jewelry 3D printers in 2023. According to Prodways, the systems experienced poor turnover and “significant operating loss.” The firm hopes the strategic reallocation of resources will strengthen its position within the global additive manufacturing market.

Elsewhere, Swedish multinational engineering firm Sandvik transitioned its additive manufacturing strategy to focus on the development of metal powders. The company also revealed plans to exit its minority stake in Italian 3D printing service provider BEAMIT and divested engineer-to-order business DWFritz Automation to private equity firm Balmoral Funds.

Sandvik chose to exit its approximately 30% stake in BEAMIT to align with its focus on metal powders for additive manufacturing. The move will build on the company’s existing material R&D efforts and metal powder portfolio. Its Osprey metal powders feature materials spanning copper, aluminum, and Ni-based superalloys.

All the news from Formnext 2024.

Who are the leaders in additive manufacturing? Vote now in the 2024 3D Printing Industry Awards!

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows 3D Systems’ headquarters in Rock Hill, South Carolina. Photo via CBRE Group.