Axtra3D Inc., a Charlotte-based manufacturer specializing in high-speed stereolithography (SLA) 3D printing systems, has successfully raised $9.75 million in its latest Series A funding round. The $4.5 million investment was led by HZG Group, highlighting strong investor confidence in Axtra3D’s innovative approach to additive manufacturing.

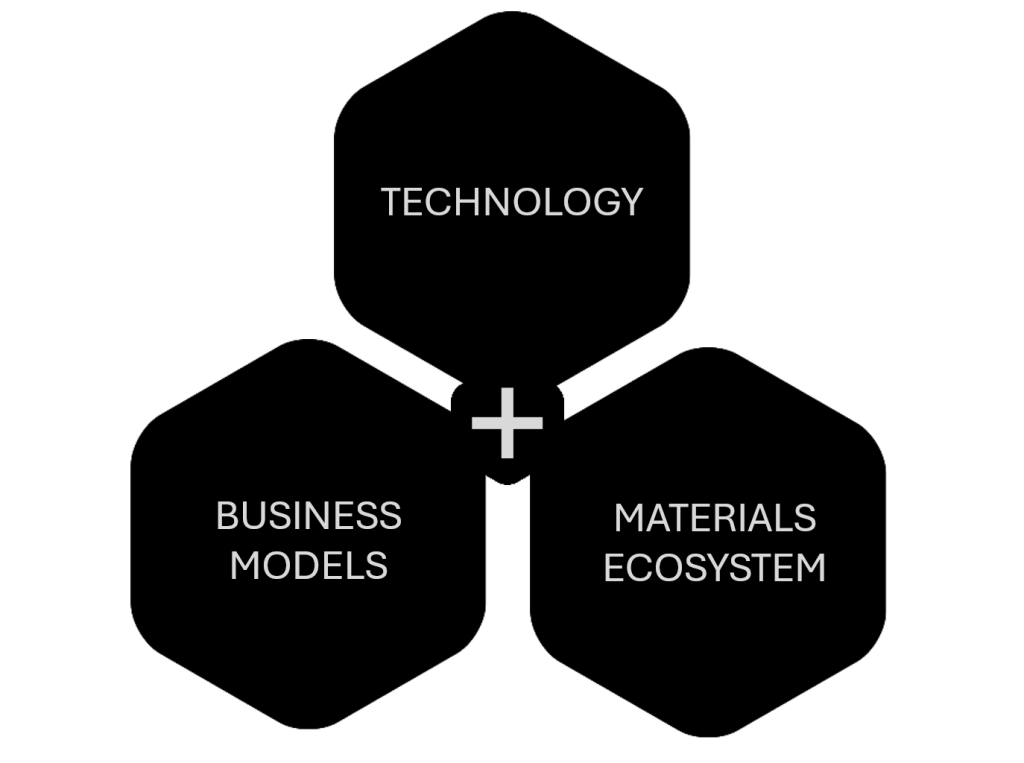

The new capital will enable Axtra3D to broaden its international footprint and diversify its product offerings. With an existing facility in Vicenza, Italy, the funds will support entry into new markets and the expansion of Axtra3D’s material ecosystem. The company’s proprietary Hybrid Photosynthesis (HPS) technology, combined with TruLayer technology, allows for the production of high-precision, high-throughput 3D printed parts. This advancement positions Axtra3D competitively within the additive manufacturing sector.

Frank Carsten Herzog, CEO of HZG Group, stated, “Axtra3D has been one of our most successful investments in additive manufacturing. Their solutions effectively address current market demands, and their leadership team has demonstrated exceptional agility in navigating industry challenges. This investment will enable Axtra3D to accelerate technological advancements and expand their market reach beyond North America and Europe.”

In 2023, Axtra3D introduced its Lumia product line, integrating HPS and TruLayer technologies to revolutionize the 3D printing process. HPS merges resin-based stereolithography with digital light processing, achieving print speeds up to 20 times faster than traditional SLA methods without compromising accuracy or surface quality. TruLayer technology ensures consistent layer formation, enhancing the mechanical properties and durability of printed parts. This combination has allowed Axtra3D to launch four distinct solutions: concept and low-volume mold printing, true silicone printing, end-use connectors, and specialized offerings for dental labs.

Gianni Zitelli, Founder and CEO of Axtra3D, commented, “This funding validates our strategic focus on customer partnerships and robust support systems. We are committed to building Axtra Academy, our dedicated customer support infrastructure, to provide comprehensive assistance and training to our users. Our flexible business models, Axtra Solutions™ and Axtra OpenAccess™, are designed to meet diverse customer needs, from service bureaus to large-scale manufacturers.”

Investments in Metal 3D Printing and Recycling

The additive manufacturing sector has recently witnessed significant investments in companies focusing on metal 3D printing and sustainable manufacturing solutions. Sun Metalon, a startup specializing in sustainable metal manufacturing, raised $21 million in a Series A funding round to enhance its new metal recycling technology. Founded in 2021 and operating in Japan and the United States, Sun Metalon aims to decarbonize the metal industry with a high-speed metal 3D printer and proprietary metal heating technology that facilitates low-energy, zero-emissions recycling of waste metal.

Similarly, Fortius Metals, a Colorado-based company specializing in metal 3D printing, secured an additional $2 million in seed funding, bringing its total to $5 million. Fortius collaborates with organizations such as the U.S. Army, Navy, Air Force, and NASA, developing proprietary aluminum welding wires designed to eliminate hot cracking in metal parts. The company plans to launch additional wire alloys with advanced properties in 2025, offering significant advantages in design performance and weight reduction for aerospace and defense applications.

Your voice matters in the 2024 3D Printing Industry Awards. Vote Now!

What will the future of 3D printing look like?

Which recent trends are driving the 3D printing industry, as highlighted by experts?

Subscribe to the 3D Printing Industry newsletter to stay updated with the latest news and insights.Stay connected with the latest in 3D printing by following us on Twitter and Facebook, and don’t forget to subscribe to the 3D Printing Industry YouTube channel for more exclusive content.

Featured Image shows a close-up of an Axtra3D 3D printer. Photo via Axtra3D.