Farsoon Technologies, a leader in industrial-grade 3D printing systems, has introduced the Flight HT601P-4, a large-format polymer powder bed fusion (PBF) system featuring four 300-watt fiber lasers. Announced shortly after its showcase at Formnext 2024, the Flight HT601P-4 is designed to enhance industrial-scale additive manufacturing by combining high-speed production with advanced automation to maximize yield and reduce costs per part.

The new system offers a substantial build volume of 600 × 600 × 600 mm (216 liters), enabling the efficient production of large components or high-volume batches. Fiber lasers in the Flight HT601P-4 achieve scanning speeds of up to 20 meters per second, significantly boosting productivity and operational efficiency. Its interchangeable build cartridge design supports continuous production workflows, minimizing downtime and maximizing throughput. Additionally, the compact footprint allows for optimized factory layouts, enhancing production yield within limited floor spaces.

Farsoon’s latest model incorporates several advanced features to maintain consistent, high-quality outputs throughout the build process. An innovative powder supply method ensures efficient and uniform recoating, while an advanced control card optimizes process control for stable laser power distribution and superior beam quality. Users can select between “Efficiency Mode,” which utilizes overlapping laser areas to enhance productivity, and “Quality Mode,” which employs single-laser scanning for applications requiring precise detailing and industry certifications.

The optical cooling system within the Flight HT601P-4 maintains optimal operating temperatures for critical components, ensuring consistent part properties and surface quality across the build cylinder. Capable of handling chamber temperatures up to 220°C, the system is suitable for processing high-performance materials such as PA6, PBT, PA11, PA12, and TPU. Farsoon’s patented multi-zone temperature control and infrared thermal monitoring ensure uniform heat distribution and real-time thermal stability adjustments, providing reliable and consistent results across the entire build surface.

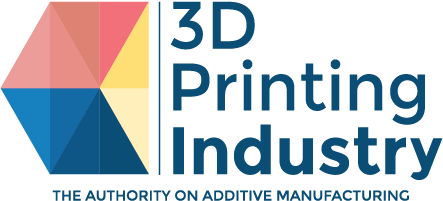

Designed for seamless integration into large-scale production environments, the Flight HT601P-4 offers a streamlined workflow. Its advanced Powder Management System supports powder recycling, mixing, and sieving, allowing multiple Flight HT601P-4 machines to operate simultaneously. Smart production line integration centralizes systems for powder handling, build cylinder transfer, part cooling, and breakout, enabling fully automated and highly efficient manufacturing processes.

Embracing an open parameter strategy, Farsoon empowers users to fine-tune material processing for unique applications. This flexibility supports innovation in industries such as aerospace, automotive, and medical, unlocking new possibilities in polymer additive manufacturing.

Research on Powder Spreadability and Market Growth in Metal 3D Printing

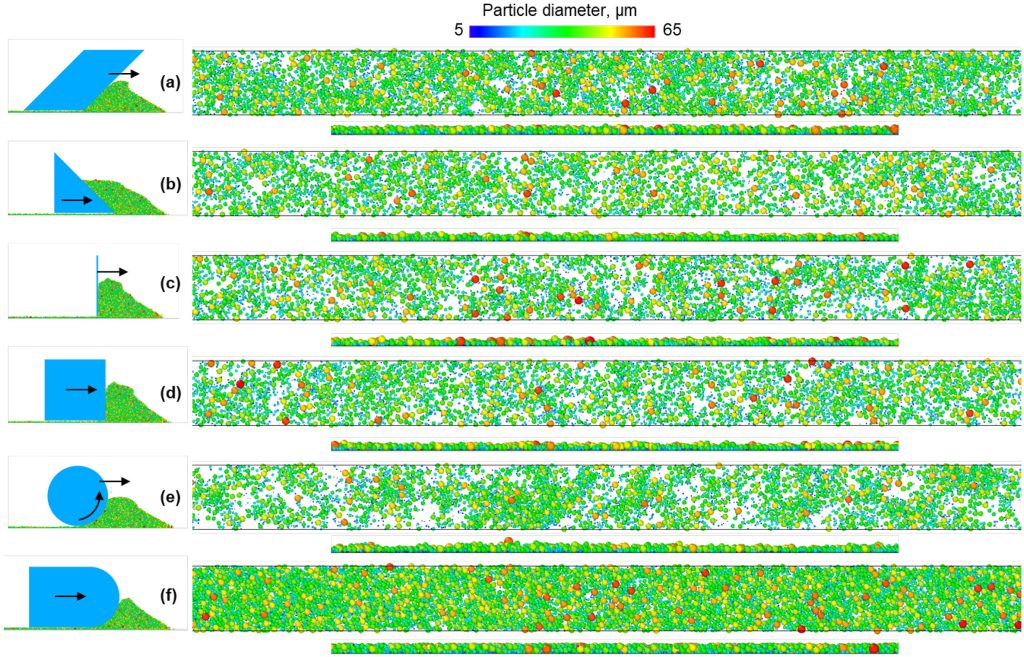

A recent study published in Particuology by researchers from the University of Leeds, University of Greenwich, and Cormica Limited evaluated how powder spreadability impacts PBF 3D printing. The review highlights the influence of powder properties, environmental conditions, and spreading systems on final part characteristics. The researchers emphasize the need for standardized characterization methods to improve powder spreadability and quality control in PBF processes.

Market intelligence firm CONTEXT reported a 45% growth in Chinese metal 3D printer shipments in the first quarter of 2024, contrasting with a decline in global industrial polymer 3D printer shipments. The report notes that while Chinese vendors experienced strong domestic demand, Western vendors faced challenges due to low capital expenditure and high inflation. The shift toward entry-level 3D printers continued, with professional users recognizing the capabilities of lower-priced models.

Your voice matters in the 2024 3D Printing Industry Awards. Vote Now!

What will the future of 3D printing look like?

Which recent trends are driving the 3D printing industry, as highlighted by experts?

Subscribe to the 3D Printing Industry newsletter to stay updated with the latest news and insights.

Stay connected with the latest in 3D printing by following us on Twitter and Facebook, and don’t forget to subscribe to the 3D Printing Industry YouTube channel for more exclusive content.

Featured image shows the he HT601P-4. Photo via Farsoon Technologies.