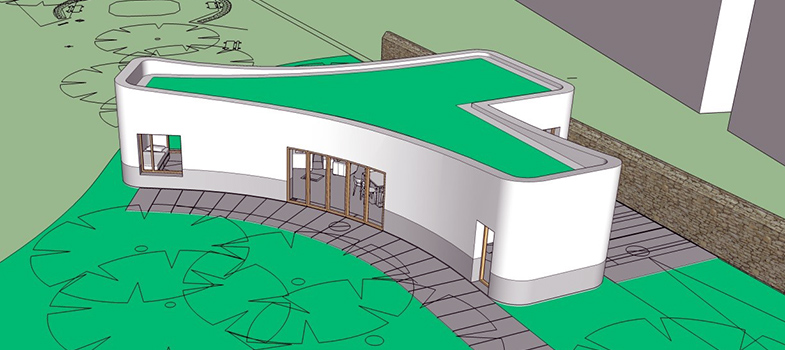

The University of Nantes, together with The Nantes Digital Sciences Laboratory (LS2N) is developing a 3D printed house project known as Yhnova.

The project will utilize the University’s Batiprint3D method, which uses 3D printing techniques to construct with concrete. And it is quite unlike the way we’re used to seeing it.

Batiprint3D

Instead of directly 3D printing with concrete as in projects like those at the Institute for Advanced Architecture of Catalonia, the university’s innovative method 3D prints large scale molds.

3D printed polyurethane is sprayed layer-by-layer as supporting structure, and then concrete is poured inside it. The outer 3D printed structure remains to form insulation, therefore making the structure a kind of reverse way of traditionally made walls.

Gif shows the Batiprint3D process. Images via Johanna Rolland on twitter.

The Yhnova project is to involve construction of a 5-room, round walled social housing building designed by architectural firm TICA. According to the University, Batiprint3D will reduce construction time, improve thermal insulation and reduce construction operating costs.

“Fully certified”

Speaking to French publication La Tribune, Benoit Furet explains how this alternative technique is beneficial. He says,

This process will reduce the construction time and the hard work of masons. They will no longer install breeze blocks, they will pilot robots. Above all, the building is fully certified. It’s better when you want to accommodate people. This is what differentiates us from Chinese or Russian projects.

The University of Nantes professor and LS2N researcher refers to the recent 3D printed house by Apis Cor and the work of Chinese company Winsun. Winsun has just announced a “billion dollar deal” to lease 3D printers to Saudi Arabia.

Not yet truly tested

As Furet says, the Batiprint3D process is beneficial as it combines 3D printing with more traditional techniques with aim of creating a habitable house. The process seems to be also beneficial in the ability to create complex structures. The robotic arm of the Batiprint3D can print structures up to 7 metres high and the planned house is considerably larger than Apis Cor’s 38m sq.

The benefits of this new 3D printing method will be truly tested in September when construction of the house begins in Nantes. If successful, the French group will have found a new way of constructing affordable social housing that can be quickly developed on-site.

If you haven’t already, make sure to place your votes for the 3D Printing Industry Awards.

For the latest news on 3D printing construction, sign up to our newsletter and follow us on twitter.

Featured image shows the Batiprint3D machine. Photo via IUTNantes.