Last Updated on April 16, 2021 by Admin

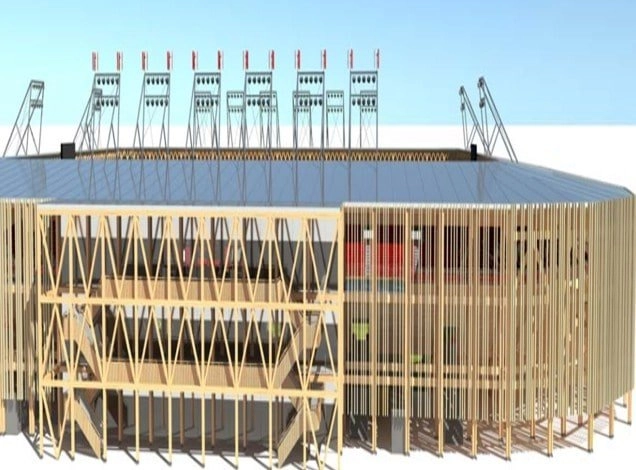

Rubner Holzbau, Italian glulam timber construction specialist, has joined hands with Bear Stadiums, advisor in sport facilities and architectural design, to develop a modular stadium concept made of glulam wood. The modular “stadiums of the future” can be constructed quickly and are cost efficient. According to Bear Stadiums and Rubner Holzbau, it takes only 4 to 8 months to assemble a modular stadium as compared to 18 to 24 months time taken by traditionally constructed stadium.

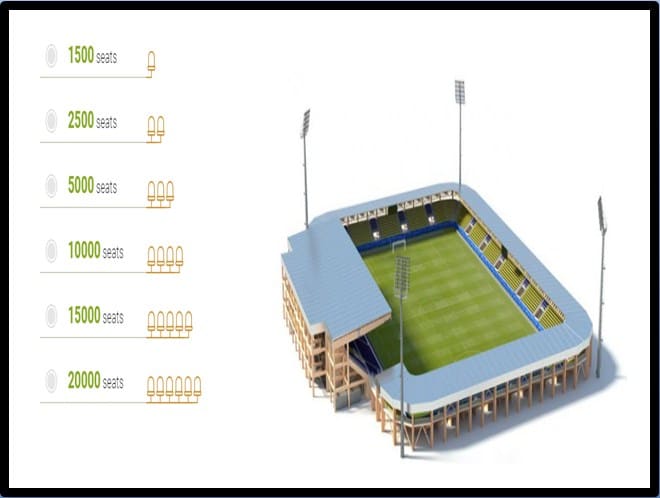

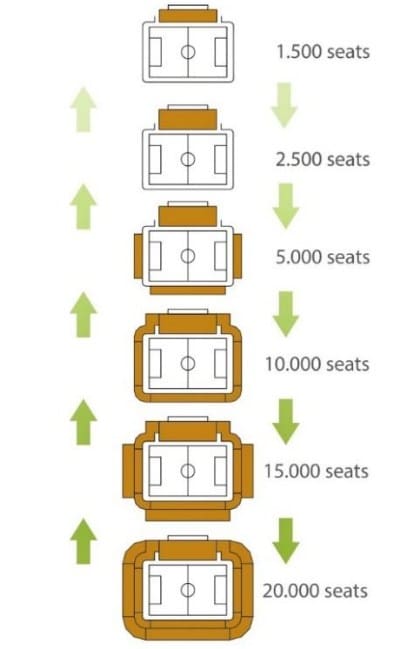

Bear Stadiums and Rubner Holzbau claim that you can choose the size of the stadium and it will be tailor-made as per your needs. The innovative modular system allows to produce and transport the modules of your stadium in 40 feet containers to any destination in the world and to assemble the stands in record time, guaranteeing fixed and limited costs.

Bear Stadiums are built to last, using wood from sustainably managed forests. Wood is a renewable resource produced by nature. It is an excellent construction material and differs from concrete and steel as it does not require fossil energy for its production. Wood is also a Carbon Sink, sequestrating carbon even after it has been turned into timber.

Bear Stadiums’s state of the art glum technology offers light, safe, ecological structure, made of natural materials and designed to reduce energy consumption. Bear Stadiums can be also be fitted with mini wind turbines and solar panels that produce the green energy necessary to power the stadium utilities, and water can be stored and recycled to irrigate the Football pitch.

Bear Stadiums are built as per FIFA and UEFA’s standards and regulations, guaranteeing perfect pitch visibility, comfortable, safe and covered seating, pitch lighting suitable for hd filming, and minimum distance between stands and pitch sideline.

Inside the mainstand, the stadiums layout include Team A and B king size locker rooms with all professional facilities, conference hall, media and interview spaces, offices, anti-doping and infirmary area, as well as all the best services for the public: bars, restaurants, hospitality lounge, sky boxes, and TV spot.

The stadium is manufactured, shipped, and assembled by Bear Stadiums’s partner Rubner Holzbau. The local contractor, appointed by the customer, carries out the earthworks, lays the foundations, hooks up the utilities, and prepares the pitch and the interior finishings. Bear Stadiums claim that it is possible to hand over the entire stadium within 4 to 8 months timeframe depending upon the size of the stadium. As the stadiums are built using glulam timber which is structurally engineered wood product comprising a number of layers bound together with ecological adhesives, it helps to reduce the greenhouse gas emissions and high energy consumption that come from traditionally constructed stadium using reinforced concrete or metal.

As modular stadiums are built with prefabricated modules, it can be easily dismantled to transform a big structure into smaller structures. The prefabricated modules can be easily taken apart and can be re-used to a great extent for other building projects. For example, a modular stadium with a capacity of 45,000 seats can be easily used later on to build several small facilities like a mid-size stadium to accommodate 25,000 seats for a soccer club and a stadium with a capacity for 20,000 with track and field facilities for other sports. Or it can also be used to accommodate several smaller sports clubs or complexes with seating capacity of 8,00 to 10,000. On the other hand a permanent concrete structure needs complete demolition in order to construct another structure on the same place.

Credits: Bear Stadiums

More recommended reads for you:

117 Requirements for Engineers & Others | CSPHCL | Last Date : 8th Aug 18

The Big 5 Construct India | 5-7 September 2018 | Mumbai

Overseas jobs In Australia | Engineers – Civil | Structural | Design

Jobs In Megha Engineering and Infrastructures Ltd | Exp 3 -10 yrs

Jobs In EYGBS (India) Private Limited | 1 – 3 yrs

Various Jobs For Engineers In AECOM

Walk-In Interview for Civil Engineers | Reliance Industries Ltd | Exp 2 – 10 yrs

Walk-In Interview for Civil Engineers | Reliance Industries Ltd | Exp 2 – 10 yrs