Chemoenzymatic Synthesis of an Enantiomerically Enriched Bicyclic Carbocycle Using Candida parapsilosis ATCC 7330 Mediated Enantioselective Hydrolysis ()

Received 27 November 2015; accepted 21 December 2015; published 24 December 2015

1. Introduction

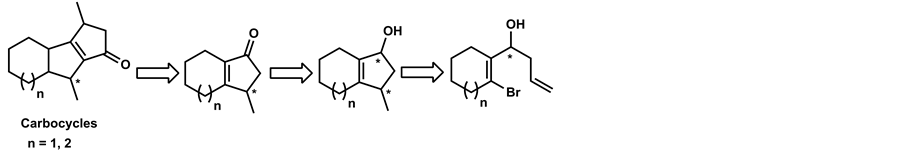

Enantiomerically enriched allylic and propargylic alcohols are very useful intermediates in the asymmetric synthesis of more complex molecules [1] [2] and are also resourceful synthons for the synthesis of various biologically active compounds [3] [4] . Several methods are available for the synthesis of such systems, e.g. enantioselective addition of chiral allylboranes [5] and allyltitanation [6] to aldehydes, asymmetric organozinc additions to aldehydes [7] [8] and the elimination of chiral vinyl sulfoxides [9] . The widely used methods for the preparation of these intermediates are enantioselective acylation of secondary allylic alcohols and enantioselective hydrolysis of the corresponding esters catalysed by enzymes and nonenzymatic chiral catalysts [1] [10] - [13] . In particular, enantiomerically pure 1-(2’-bromocycloalkenyl)-3-buten-1-ol and its derivatives can be cyclised and utilized for the synthesis of optically active condensed carbocycles (Scheme 1). These bicyclic allylic alcohols can be oxidized to bicyclicenones which are important chiral synthons for the development of biologically active compounds [14] [15] and is an important structural feature of many natural products [16] - [19] . Synthesis of various bicyclicenones by intramolecular cyclization has been described in literature [20] - [22] . Intramolecular tri butyl tin hydride mediated cyclization of optically active 1-(2’-bromocycloalkenyl)-3-buten-1-ols is a potential route for the synthesis of optically pure condensed carbocyles [23] - [25] . However, synthesis of optically pure carbocycles from the corresponding chiral intermediates i.e., enantiopure allylic alcohols has not been reported.

Various chemical [1] [22] and biocatalytic [26] - [29] methods are available for the synthesis of enantiomerically pure aryl/alkyl-allyl alcohols. Lipases, generally obtained from microorganisms, are the most widely used enzymes in organic synthesis, mainly due to their high enantioselectivity [30] - [32] , the possibility of using non- conventional solvents like organic solvents and ionic liquids [33] and are economical, stable, and easy to reprocess. Among the methods reported, only few specific examples are available for the lipase mediated resolution of aliphatic cyclic allylic alcohols. In this context, Mc Cubbin et al. resolved a series of aryl and aliphatic vinyl chlorohydrins by enzymatic kinetic resolution using Amano lipase AK. The resolution of alkyl and cyclic aliphatic vinyl chlorohydrins was a fast reaction but the enantioselectivity was lower as compared to that of aryl substrates [34] . Takabe et al. reported the one-pot acid promoted catalyzed cyclisation of geranyl amine N-oxide to synthesise 1-acetyl-4,4-dimethyl-1-cyclohexene which in turn was reduced and resolved by Amano lipase AK with good enantioselectivity [35] . Similarly Kuriata et al. synthesized chiral bicycle [3.1.0] hexane derivatives via chemoenzymatic synthesis in which the synthesized (+)-1-[(1S,5R)-6,6-dimethylbicyclo[3.1.0] hex-2-en-2- yl)]ethanol was resolved by a transesterification strategy using Amano PS lipase from B. cepacia [36] . However, the enantioselective hydrolysis of the corresponding acetate using various lipases from B. cepacia and C. rugosa was unsuccessful. The versatility of the biocatalyst Candida parapsilosis ATCC 7330 was established in our lab. This yeast is used for the preparation of a variety of enantiopure compounds by deracemization [36] - [39] , asymmetric reduction [40] [41] and oxidative kinetic resolution [42] .

This biocatalyst is also reported for resolution of N-protected amino acid esters with excellent enantioselectivity (E = 40 to >500) [43] . In continued efforts to expand the scope of the biocatalyst, herein we report the enantioselective hydrolysis of 1-(2-bromocycloalkenyl) but-3-en-1-yl acetates using fermenting cells of C. parapsilosis ATCC 7330. These cyclic acetates with different functionalities (bromo and allyl/propargyl), in addition to yielding important chiral synthons, provide an interesting set of substrates to study hydrolysis using C. parapsilosis ATCC 7330. To the best of our knowledge, this is the first report for the synthesis of enantiomerically enriched1-(2-bromocycloalkenyl) but-3-en-1-ol and its derivatives by biocatalyst mediated enantioselective hydrolysis. The enantiopure enriched 1-(2-bromocycloalkenyl) but-3-en-1-ol thus obtained was further cyclized to 3-methyl-2,3,4,5,6,7-hexahydro-1-H-inden-1-ol which can be used for the synthesis of optically pure condensed carbocycles.

Scheme 1. Retrosynthetic route for carbocycle from bicyclic allylic alcohol.

2. Result and Discussion

Initially, the model substrate (RS)-1-(2-bromocyclohex-1-en-1-yl) but-3-en-1-yl acetate 1a was subjected to enantioselective hydrolysis with commercially available lipases (Lipase PS, Amano lipase AK and CAL-B) under reported conditions [44] . All the lipases tested gave <5% conversion even after 3 days. Further, enantioselective hydrolysis of (RS)-1-(2-bromocyclohex-1-en-1-yl) but-3-en-1-yl acetate 1a was carried out with the resting cells (14 h culture) of Candida parapsilosis ATCC 7330 using our earlier reported conditions [43] . In this reaction, the substrate 1a (0.2 mmol) was incubated with the resting cells of C. parapsilosis ATCC 7330 suspended in water (20 mL; 6 g wet cell mass from 300 mL culture) using ethanol as a cosolvent (0.5% v/v). The product 2a was obtained with moderate conversion (26%) and only 20% ee as analysed by gas chromatography (GC) using a chiral column (Scheme 2). The poor enantioselectivity could be due to the presence of multiple hydrolases with opposite enantioselectivities for the same substrate. Next, the substrate 1a (0.08 mmol) was dissolved in cosolvent ethanol (0.5% v/v) and directly added in to a 12 h fermenting culture (50 mL) at 25˚C and incubation was continued. After 48 h the product was obtained with an improvement in ee (89%) but the conversion was very poor (8%).

To further improve the conversion and enantiomeric excess, the reaction conditions were optimized with 1a as follows.

2.1. Optimization of Cosolvents

Reportedly, conversion and enantioselectivity in lipase catalysed hydrolysis can be improved by the addition of a suitable cosolvent [45] . First, the reaction was carried out in the absence of a cosolvent and the product was obtained with 82% ee and 19% conversion. When the reaction was carried out with ethanol, isopropyl ether or acetone as a cosolvent, the conversion dropped from 19 to 8%. Similar observations have been reported by Szymanski et al. for the enzymatic hydrolysis of α-acetoxyamides when acetone was used as a cosolvent [46] . Dioxane and DMSO showed moderate conversion (25% - 37%). All long chain hydrophopic cosolvents (n-octane, isooctane and hexane) gave good conversion (up to 56%). This result is consistent with the literature reports that hydrophobic solvents favor the binding of hydrophobic substrates to lipase [27] . Among the cosolvents tested in this study, only hexane showed reasonable conversion (40%) and good ee (90%) (Figure 1).

![]()

Scheme 2. Enantioselective hydrolysis of (RS)-1a.

2.2. Optimization of Reaction Time

Further, the reaction time was varied from 12 to 60 h using hexane as cosolvent. It was found that 48 h showed improvement in both conversion (40%) and enantiomeric excess (89.6%) (Table 1). Further increase in the reaction time resulted in decrease in ee (82.2%). Hence 48 h was chosen as the optimum incubation time for further experiments.

2.3. Effect of Temperature

To study the effect of temperature on conversion and ee of enantioselective hydrolysis, the reaction was performed at various temperatures from 25˚C - 35˚C. The product 2a was obtained with good conversion (40%) and ee (89%) at 25˚C (Table 2). With increasing temperature (30˚C & 35˚C), the conversion also increased (66 & 68% respectively) but the enantiomeric excess reduced sharply (61 & 57% respectively) (Table 2). This Candida grows best at 25˚C [36] , which supports the observation that maximum conversion is obtained at 25˚C. All further experiments were carried out at 25˚C.

2.4. Optimization of Substrate Concentration

In whole cell biocatalysis, conversion and enantioselectivity can be controlled by optimizing the substrate concentration due to the presence of multiple enzymes with opposite stereo preferences and different Km values for the same substrate [45] . The substrate 1a was added in varied concentrations (1 - 2.5 mM) keeping all the conditions identical (Figure 2). Notably, higher conversion (53%) was observed with low substrate concentration (1 mM), while the enantiomeric excess was moderate (75%). At a substrate concentration of 1.5 mM, the enanti-

![]()

Figure 2. Optimization of substrate concentration (1a).

![]()

Table 1. Optimization of reaction time for improved conversion and enantiomeric excess.

omeric excess increased to 89% with good conversion (39%). Further increase in the substrate concentration showed a drop in conversion however the ee was maintained. Hence, 1.5 mM of substrate was chosen as the optimum substrate concentration.

2.5. Substrate Scope

Under the optimized reaction conditions, three substrates were used (Scheme 3). The experiment with substrate 1a yielded product (R)-1-(2-bromocyclohex-1-en-1-yl)but-3-en-1-ol 2a in 33% isolated yield and 89% ee (E = 31) (Table 3, entry 2a). To further explore the substrate scope of this biocatalyst, substrate 1b (Scheme 3) was subjected to hydrolysis using fermenting cells of C. parapsilosis ATCC 7330. Initially, under the optimized reaction time of 48 h, a moderate conversion (20%) was obtained with excellent ee (>99%). The conversion was further improved to 32% by extending the reaction time to 60 h and the product (R)-1-(2-bromocyclohept-1-en-1-yl) but-3-en-1-ol 2b was isolated with moderate yield (29%) and excellent ee (> 99%) (E => 200) (Table 3, entry 2b). The obtained high enantioselectivity suggests that the substrate with the 7-membered ring is seemingly better than the one with the 6-membered ring for the biocatalyst. Another substrate 1c (Scheme 3) with an alkyne chain was subjected for enantioselective hydrolysis and the product (R)-1-(2-bromocyclohex-1-en-1-yl) but-3- yn-1-ol 2c was obtained with excellent ee (>99%) in lesser reaction time (12h) compared to substrates 1a & 1b. Further increase in the reaction time resulted in decrease in ee. The product 2c was isolated in 42% yield and 99% ee (E => 500) (Table 3, entry 2c).

Scheme 3. Enantioselective hydrolysis of (RS)-1a-c.

![]()

Table 3. Enantioselective hydrolysis of (RS)-1a-1c.

aAbsolute configuration was assigned by comparing specific rotation value with the analogue substrate [47] ; bConversion and ee was determined by GC using Chirasil Dex CB chiral column; cEnantiomeric excess of the unreacted acetates were determined after hydrolysis using 5% methanolic KOH; dEnantioselectivity ratios were calculated according to: E = ln[(eep(1 − ees)/( eep+ees)]/ln[(eep(1 + ees)/(eep + ees) [48] ; E values in the range 200 - 500 are mentioned as >200, more than 500 as >500.

1H NMR (500 MHz,CDCl3) δ:5.86 (dd, J = 8,5.5 Hz, 1H), 5.74 - 5.82 (m, 1H), 5.10 - 5.15 (ddd, J = 17, 3.5, 1.5 Hz, 1H), 5.06 - 5.09 (ddd, J = 9.5, 1.5, 0.5 Hz, 1H), 2.51 - 2.55 (m, 2H), 2.44 - 2.50 (m, 1H), 2.36 - 2.41 (m, 1H), 2.08 - 2.17 (m, 2H), 2.06 (brs, 3H), 1.66 - 1.72 (m, 3H), 1.61 - 1.64 (m, 1H); 13C NMR (125 MHz, CDCl3) δ: 169.9, 133.7, 133.3, 121.3, 117.6, 75.7, 36.7, 36.6, 25.9, 24.5, 21.9, 20.9; HRMS for C12H17O2Br (Cal: 295.0310 [M + Na]+, Found: 295.0310); ee = 59%, retention times 15.0 (S, major), 15.5 min (R, minor); [α] D25 + 1.1 (c 1, CHCl3).

1H NMR (500 MHz, CDCl3) δ: 5.74 - 5.79 (m, 2H), 5.06 - 5.11 (m, 1H), 5.03 - 5.04 (m, 1H), 2.72 - 2.79 (m, 2H), 2.37 - 2.43 (m, 1H), 2.27 - 2.35(m, 1H), 2.19 - 2.26 (dd, J = 6.5, 5 Hz, 2H), 2.02 (brs, 3H), 1.70 - 1.74 (m, 2H), 1.53 - 1.56 (m, 3H), 1.38 - 1.52 (m, 1H); 13C NMR (125 MHz, CDCl3) δ: 169.9, 138.7, 133.2, 125.0, 117.7, 76.7, 41.5, 36.7, 31.6, 27.9, 25.9, 25.1, 20.9; HRMS forC13H19O2Br (Cal: 309.0466 [M + Na]+, Found: 309.0466); ee = 46%, retention times 20.3 (S, major), 21.5 min (R, minor); [α] D25 + 1.7 (c 1, CHCl3).

1H NMR (500 MHz, CDCl3) δ: 5.87 - 5.89 (m, 1H), 2.56 - 2.66 (m, 2H), 2.52 - 2.54 (m, 2H), 2.18 - 2.28 (m, 1H), 2.08 (s, 3H), 1.97 - 1.98 (t, J = 2.5 Hz, 1H), 1.62 - 1.75 (m, 4H), 1.59 (brs, 1H); 13CNMR (125 MHz, CDCl3) δ: 169.7, 133.1, 122.1, 79.4, 74.0, 70.2, 36.7, 26.0, 24.4, 22.4, 21.8, 20.8; HRMS for C12H15O2Br (Cal: 293.0153 [M + Na]+, Found: 293.0154); ee => 99%, retention times19.4 (R, minor), 19.8 min (S, major); [α] D25 + 3.2 (c 0.5, CHCl3).

1H NMR (500 MHz,CDCl3) δ: 5.78 - 5.86 (m, 1H), 5.12 - 5.18 (m, 2H), 4.78 - 4.81 (dd = t, J = 6.5 Hz, 1H), 2.50 - 2.52 (m, 2H), 2.28 - 2.34 (m, 3H), 2.04 - 2.10 (m, 1H), 1.63 - 1.74 (m, 5H); 13C NMR (125 MHz, CDCl3) δ:136.9, 134.3, 120.3, 118.0, 73.2, 38.9, 36.8, 25.4, 24.7, 22.1; ee = 89%; retention times 15.0 (S, minor), 15.5 min (R, major); [α]D25 + 25.4 (c 0.5, CHCl3).

Lipase PS (from Burkholderia cepacia) and Amano lipase AK (from Pseudomonas fluorescence) were obtained from Amano Pharmaceuticals Co., Nagoya, Japan. CAL B (Candida antarctica lipase B, Novozym 435) was purchased from Sigma. Candida parapsilosis ATCC 7330 was obtained from ATCC (Manassas, VA) and maintained at 4˚C in yeast malt agar medium that contained 5 g/L peptic digest of animal tissue, 3 g/L malt extract, 3 g/L yeast extract, 10 g/L dextrose and 20 g/L agar. All chemicals used were of analytical grade and distilled prior to use. TLC was carried out on Kieselgel 60 F254 aluminium sheets (Merck1.05554). 1H and 13C NMR spectra were recorded in CDCl3 solution on a Bruker AVANCE III 500 MHz spectrometer. Chemical shifts are expressed in ppm values using TMS as an internal standard. The enantiomeric excess was determined by gas chromatography using Perkin Elmer Clarus 600 gas chromatograph and Shimadzu GC 2014 gas chromatograph fitted with flame ionisation detector using VARIAN Chirasil Dex CB chiral column (0.25 μm × 25 mm × 30 m). The injector and detector were set at 220˚C, respectively. Nitrogen was used as the carrier gas. Optical rotations were determined using Autopol-IV automatic polarimeter.

3.2. General Procedure for the Synthesis of (RS)-1a-1c [23]

Tin powder (1.5 mmol) was suspended in a mixture of water (2 mL) and diethyl ether (2mL). To this mixture allyl bromide (3 mmol) was added and treated with few drops of 48% hydrobromic acid and the mixture was stirred well for 5 min at RT. To this reaction mixture bromoaldehyde (1 mmol) was added and the resultant mixture was stirred for 6 h at RT (reaction was monitored by TLC). After the complete conversion, the reaction was quenched with water (5 ml) and extracted with 20% dichloromethane/hexane mixture (10 mL × 3). The organic layers were combined and dried over anhydrous sodium sulfate and concentrated under reduced pressure. The crude reaction mixture was purified by silica gel column chromatography using hexane/ethyl acetate (9:1) as a mobile phase (Yield: 60% - 80%). The respective bromo alcohol (1 mmol) was stirred with (2 mL) of acetic anhydride containing catalytic amount of sodium acetate for 24 h at room temperature. The progress of the reaction was monitored by TLC. After the completion of reaction, the reaction mixture was diluted with dichloromethane and washed with water. The organic layer was dried over sodiumsulphate and concentrated under reduced pressure. The crude reaction mixture was purified by column chromatography over silica gel (100 - 200 mesh) using hexane/ethyl acetate mixture (9:1) as a mobile phase to obtain the pure product (Yield: 70% - 80%).

Scheme 4. Radical cyclization of 2a.

3.3. Growth Conditions for Candida parapsilosis ATCC 7330

Candida parapsilosis ATCC 7330 was pre-cultured for 12 h at 25˚C with shaking at 200rpm in yeast malt broth medium that contained 5 g/L peptic digest of animal tissue, 3 g/L malt extract, 3 g/L yeast extract and 10 g/L dextrose. The pre-cultured broth, 4 mL [4% (v/v)] was transferred to a 500 mL Erlenmeyer flask that contained 96 mL of yeast malt broth. The culture was grown on rotatory shaker at 25˚C and 200 rpm for 12 h.

3.4. Typical Procedure for Enantioselective Hydrolysis Using Candida parapsilosis ATCC 7330

To the 500 mL Erlenmeyer flask that contained 12 h cultivated cells (100 mL culture), the substrate (racemic acetate, 1.5 mM) in 500 μL of hexane as co-solvent was added and the incubation was continued at 25˚C and 200 rpm. After getting the maximum conversion and enantiomeric excess of the product, the cells were centrifuged at 6000 rpm for 10 min. The formed product and the remaining substrate were extracted from the supernatant using ethylacetate. The organic layer was dried over anhydrous sodium sulphate. The solvent was removed by evaporation and the crude extract was purified by silica gel column chromatography using hexane/ ethyl acetate (95:05) as a mobile phase eluent.

3.5. General Procedure for the Synthesis of 3a and 3b [23]

The respective enantiomerically enriched (R)-1-(2-bromocyclohex-1-en-1-yl)but-3-en-1-ol 2a (1 mmol) was dis- solved in ethanol (25 mL). To this bis-tri-n-butyltinoxide (5 mol%), sodium borohydride (1 mol) and catalytic amount of azobisisobutyro nitrile (AIBN) were added. The reaction mixture was refluxed for 3 h at 80˚C under N2 atmosphere and the reaction was monitored by TLC. After the completion of reaction, the reaction mixture was concentrated under reduced pressure. The products were purified by column chromatography over silica gel (100 - 200 mesh) using hexane/ethyl acetate mixture (9:1) as a mobile phase to obtain the cyclized product 3a and 3b (Yield: 70% - 80%).

3.6. Spectroscopic Characterization

3.6.1. (S)-1-(2-bromocyclohex-1-enyl) but-3-enyl acetate 1a

1H NMR (500 MHz,CDCl3) δ:5.86 (dd, J = 8,5.5 Hz, 1H), 5.74 - 5.82 (m, 1H), 5.10 - 5.15 (ddd, J = 17, 3.5, 1.5 Hz, 1H), 5.06 - 5.09 (ddd, J = 9.5, 1.5, 0.5 Hz, 1H), 2.51 - 2.55 (m, 2H), 2.44 - 2.50 (m, 1H), 2.36 - 2.41 (m, 1H), 2.08 - 2.17 (m, 2H), 2.06 (brs, 3H), 1.66 - 1.72 (m, 3H), 1.61 - 1.64 (m, 1H); 13C NMR (125 MHz, CDCl3) δ: 169.9, 133.7, 133.3, 121.3, 117.6, 75.7, 36.7, 36.6, 25.9, 24.5, 21.9, 20.9; HRMS for C12H17O2Br (Cal: 295.0310 [M + Na]+, Found: 295.0310); ee = 59%, retention times 15.0 (S, major), 15.5 min (R, minor); [α] D25 + 1.1 (c 1, CHCl3).

GC conditions: Perkin Elmer Clarus 600 gas chromatograph. The initial column temperature of 100˚C was held for 1 min, then raised to150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 180˚C at a rate of 1˚C/min and finally held at 170˚C for 3 min.

3.6.2. (S)-1-(2-bromocyclohept-1-enyl) but-3-enyl acetate 1b

1H NMR (500 MHz, CDCl3) δ: 5.74 - 5.79 (m, 2H), 5.06 - 5.11 (m, 1H), 5.03 - 5.04 (m, 1H), 2.72 - 2.79 (m, 2H), 2.37 - 2.43 (m, 1H), 2.27 - 2.35(m, 1H), 2.19 - 2.26 (dd, J = 6.5, 5 Hz, 2H), 2.02 (brs, 3H), 1.70 - 1.74 (m, 2H), 1.53 - 1.56 (m, 3H), 1.38 - 1.52 (m, 1H); 13C NMR (125 MHz, CDCl3) δ: 169.9, 138.7, 133.2, 125.0, 117.7, 76.7, 41.5, 36.7, 31.6, 27.9, 25.9, 25.1, 20.9; HRMS forC13H19O2Br (Cal: 309.0466 [M + Na]+, Found: 309.0466); ee = 46%, retention times 20.3 (S, major), 21.5 min (R, minor); [α] D25 + 1.7 (c 1, CHCl3).

GC conditions: Shimadzu GC 2014 gas chromatograph. The initial column temperature of 120˚C was held for 1 min, then raised to 150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 4 min.

3.6.3. (S)-1-(2-bromocyclohex-1-enyl) but-3-ynyl acetate 1c

1H NMR (500 MHz, CDCl3) δ: 5.87 - 5.89 (m, 1H), 2.56 - 2.66 (m, 2H), 2.52 - 2.54 (m, 2H), 2.18 - 2.28 (m, 1H), 2.08 (s, 3H), 1.97 - 1.98 (t, J = 2.5 Hz, 1H), 1.62 - 1.75 (m, 4H), 1.59 (brs, 1H); 13CNMR (125 MHz, CDCl3) δ: 169.7, 133.1, 122.1, 79.4, 74.0, 70.2, 36.7, 26.0, 24.4, 22.4, 21.8, 20.8; HRMS for C12H15O2Br (Cal: 293.0153 [M + Na]+, Found: 293.0154); ee => 99%, retention times19.4 (R, minor), 19.8 min (S, major); [α] D25 + 3.2 (c 0.5, CHCl3).

GC conditions: Shimadzu GC 2014 gas chromatograph. The initial column temperature of 120˚C was held for 1 min, then raised to 150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 4 min.

3.6.4. (R)-1-(2-bromocyclohex-1-enyl) but-3-en-1-ol 2a [20]

1H NMR (500 MHz,CDCl3) δ: 5.78 - 5.86 (m, 1H), 5.12 - 5.18 (m, 2H), 4.78 - 4.81 (dd = t, J = 6.5 Hz, 1H), 2.50 - 2.52 (m, 2H), 2.28 - 2.34 (m, 3H), 2.04 - 2.10 (m, 1H), 1.63 - 1.74 (m, 5H); 13C NMR (125 MHz, CDCl3) δ:136.9, 134.3, 120.3, 118.0, 73.2, 38.9, 36.8, 25.4, 24.7, 22.1; ee = 89%; retention times 15.0 (S, minor), 15.5 min (R, major); [α]D25 + 25.4 (c 0.5, CHCl3).

GC conditions: Perkin Elmer Clarus 600 gas chromatograph. The initial column temperature of 100˚C was held for 1 min, then raised to 150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 3 min. Split Ratio = 1:10. Flow rate = 1.5 ml/min.

3.6.5. (R)-1-(2-bromocyclohept-1-enyl) but-3-en-1-ol 2b [20]

1H NMR (500 MHz, CDCl3) δ: 5.79 - 5.88 (m, 1H), 5.13 - 5.19 (m, 2H), 4.78 - 4.81 (dd = t, J = 7 Hz, 1H), 2.74 - 2.84 (ddd, J = 11.5, 7, 3.5 Hz, 2H), 2.28 - 2.34 (m, 4H), 1.75 - 1.80 (m, 3H), 1.55 - 1.62 (m, 2H), 1.50 - 1.55 (m, 2H); 13C NMR (125 MHz, CDCl3) δ:142.2, 134.3, 123.4, 117.9, 74.7, 41.6, 39.0, 31.6, 27.3, 26.3, 25.3; ee => 99%; retention times 20.3 (S, minor), 21.5 min (R, major); [α] D25 + 15.8 (c 0.6, CHCl3).

GC conditions: Shimadzu GC 2014 gas chromatograph. The initial column temperature of 120˚C was held for 1 min, then raised to 150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 4 min.

3.6.6. (R)-1-(2-bromocyclohex-1-enyl) but-3-yn-1-ol 2c [21]

1H NMR (500MHz,CDCl3) δ: 4.89 - 4.91 (dd = t, J = 6.5 Hz 1H), 2.49 - 2.54 (m, 2H), 2.47 - 2.49 (m, 2H), 2.46 - 2.47 (m, 1H), 2.05 - 2.06 (dd = t, J = 3 Hz, 1H), 1.63 - 1.74 (m, 5H), 1.24 (s, 1H); 13C NMR (125 MHz, CDCl3) δ: 136.1, 121.0, 80.5, 72.3, 70.7, 36.8, 25.3, 24.7, 24.6, 22.0; ee = > 99%, retention times 19.4 (R, major), 19.8 min (S, minor); [α] D25 + 12.2 (c 0.5, CHCl3).

GC conditions: Shimadzu GC 2014 gas chromatograph. The initial column temperature of120˚C was held for 1 min, then raised to150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 4 min.

3.6.7. (1R, 3R)-2,3,4,5,6,7-hexahydro-3-methyl-1-H-inden-1-ol 3a

1H NMR (400 MHz, C6D6) δ:4.46 - 4.47 (d, J = 6.4 Hz 1H); 2.56 (brs, 1H); 2.15 - 2.19 (m, 1H); 1.85 - 1.90 (m, 3H); 1.50 - 1.66 (m, 7H); 0.86 - 0.88 (d, J = 6.8 Hz 3H); 13C NMR (100 MHz, CDCl3) δ: 143.9, 135.6, 78.6, 42.6, 39.6, 23.5, 22.8, 22.7, 22.7, 19.5; HRMS for C10H16O (Cal: 151.1123 [M]+, Found: 151.1121); (Diasteromeric ratio 1:1) ee = > 88%; retention times 8.52 min (R, major), 8.60 min (S, minor); [α] D25 + 8.3 (c 0.5, CHCl3).

GC conditions: Shimadzu GC 2014 gas chromatograph. The initial column temperature of 120˚C was held for 1 min, then raised to 150˚C at a rate of 8˚C/min and held at 150˚C for 2 min. Further the temperature raised to 170˚C at a rate of 1˚C/min and finally held at 170˚C for 4 min.

4. Conclusion

Enantiomerically enriched 1-bromohexa-1,5-dien-3-ols 2a-2c were synthesized with good ee (up to >99%) by enantioselective hydrolysis from the corresponding racemic acetates using fermenting cells of C. parapsilosis and are reported here for the first time. The reaction parameters like cosolvent (hexane), incubation time (12 - 60 h), temperature (25˚C) and substrate concentration (1.5 mM) were optimized to obtain maximum conversion and enantiomeric excess. Notably, the product 1-(2-bromocyclohex-1-en-1-yl) but-3-yn-1-ol 2c was obtained with good yield and excellent ee in less reaction time than the other two substrates (E => 500). (R)-1-(2-bromocyclo- hex-1-en-1-yl)but-3-en-1-ol was used as chiral starting material for the first time to prepare enantiomerically enriched (1R, 3R)-3-methyl-2,3,4,5,6,7-hexahydro-1-H-inden-1-ol and (1R, 3S) 3-methyl 2,3,4,5,6,7-hexahydro- 1-H-inden-1-ol with good ee (>85% ) via a chemoenzymatic approach.

Acknowledgements

One of the authors [TS] thanks UGC, New Delhi for Senior Research Fellowship, SAIF, IIT Madras for instrumentation facilities and Mr. T. Rathnavel Pandian for assistance in optimization study. TKD and NP thank ITC Life Sciences Technology Centre, Bangalore for providing the necessary infrastructure to carry out the experiments. Professor K. K. Balasubramanian, INSA Senior Scientist, Department of Biotechnology, IIT Madras is thanked for reviewing the paper and providing valuable input. Dr. Sowmyalakshmi Venkataraman, IIT Madras for helping with the analysis.

Disclaimer

All views expressed herein are authors’ views and in no way, expressed or implied, are that of or necessarily represent the positions of ITC Limited, my current employer.

NOTES

*Corresponding authors.