Tom's Hardware Verdict

Sovol’s SV06 ACE is a super affordable, speedy bedslinger in the style of Prusa’s i3 machines. It has excellent quality at speed thanks to Klipper, and comes with a surprising number of perks, such as a built-in camera and large touchscreen.

Pros

- +

Direct drive

- +

Quality build

- +

Auto bed leveling

- +

Klipper

- +

Mainsail access

- +

Built-In camera

Cons

- -

No upgrade path from Sovol 6 to ACE

Why you can trust Tom's Hardware

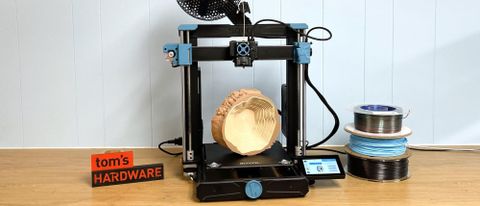

Sovol strikes again. This time with an improved version of the Sovol SV06 bedslinger, which is heavily inspired by the Prusa MK4S. Like its inspiration, the Sovol SV06 ACE (Advanced Compensation Engine) is an open-source machine with a high flow hotend, super speeds, and one-touch bed leveling. Unlike the Prusa, this is a budget-friendly 3D printer that costs only $299.

Corners were no doubt cut to produce the machine, but other than a whiny cooling fan, we found nothing troubling. In fact, the SV06 ACE has something Prusa fans crave: a built-in camera for monitoring and a simple Mainsail interface thanks to its use of stock Klipper.

The biggest improvement is its speed – the SV06 ACE boasts speeds up to 600mm/s and easily prints at 300mm/s with good quality. This is mostly due to Klipper and a high-flow nozzle previously seen on the Sovol 07.

One disappointment for anyone who may have purchased last year’s SVO6 is you can’t upgrade the older printer to an ACE. This is simply a new model with a lot of new parts.

Retailing at $299 and currently on sale for $269, the Sovol SV06 shows that you don’t need to spend a bundle for a fast printer. With cruising speeds of 300mm/s and a respectable 13-minute and 6-second Benchy, the Sovol sv06 ACE is one of the best 3D printers we tested at this price.

Specifications: Sovol SV06 ACE

| Build Volume | 220 x 220 x 250 mm (8.6 x 8.6 x 9.84 in) |

| Material | PLA/PETG/TPU (up to 300 degrees) |

| Extruder Type | Direct drive |

| Nozzle | .4mm (high flow) |

| Build Platform | PEI spring steel flex plate |

| Bed Leveling | Bed Leveling Automatic |

| Filament Runout Sensor | Yes |

| Connectivity | USB, WiFi, LAN |

| Interface | Touch Screen |

| Machine Footprint | 497 x 388 x 611 mm (19.5 x15.2 x 24in) |

| Machine Weight | 9 KG (19.8lbs) |

Sovol SV06: Included in the Box

The Sovol SV06 comes with everything you need to get your printer set up. You get tools to build and maintain the printer, side cutters, a plastic scraper, a spare nozzle, and a microSD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

You also get a PDF copy of the manual, a copy of OrcaSlicer and a sample model in both pre-sliced .gcode and .stl format.

Design of the Sovol SV06

The Sovol SV06 ACE is the successor to Sovol’s SV06 and was also inspired by the Open Source RepRap movement (aside from Prusa’s i3 line of printers). The SV06 ACE has a few tricks up its sleeve, making it cheaper and offering a few extra features you won’t find on the MK4S.

Sovol sticks to the classic i3 form while using injection molded parts in Sovol turquoise blue. It’s got a square “Ender Size” bed (220 x 220mm) and a nice new touchscreen with an easy-to-use interface. The powerful planetary drive extruder and an all-metal hotend now gets a boost from the high-flow nozzle we’ve seen on the previous Sovol SV07.

They ditched the X-axis bearings for metal wheels riding on metal rods, which gives nice, smooth movement without all the wear and tear of plastic POM wheels. The belt tensioners have easy-to-use knobs that also add a little flare to the printer’s design. The Z axis has been beefed up with 10mm rods with linear bearings and has dual independent motors capable of performing Z tilt compensation.

The SV06 ACE does away with the magnetic probe for a pressure sensor built right into the hotend – it now taps the bed to build a mesh for automatic leveling. It also has accelerometers in the tool head and the bed for Klipper’s vibration compensation, which reduces unsightly ringing artifacts caused by vibration.

There's a built-in camera so you can monitor your prints visually from Klipper’s Mainsail screen. Klipper also makes sending files extremely easy over WiFi without needing to talk to a Cloud server, and there’s a port for a USB drive.

Assembling the Sovol SV06 ACE

The Sovol SV06 ACE requires a tiny bit of assembling, but you can have it together in under half an hour. You’ll need to attach the gantry to the base with bolts, then screw the power supply to the gantry and screw the extruder to its pre-mounted plate. The screen will need to be plugged in and screwed onto the frame. Wires are well labeled, and the printed instructions are enough to direct you.

Once you get it together, take a moment to check the belts and eccentric nuts for tightness. The belts have adjustment knobs to make this step very simple.

Leveling the Sovol SV06 ACE

The Sovol SV06 ACE has hands-free auto leveling. It will level the bed turning its initial calibration and then double-check the level before each print. There’s no need to set the Z height, though if you do have issues it can be easily tweaked through the tuning menu.

Loading Filament on the Sovol SV06

Loading filament is very simple. Simply select “Load Filament” from the menu, select the type of material you are loading, and then push the filament into the top of the extruder.

Reverse the process to change colors or remove the filament.

Preparing Files / Software for Sovol SV06 ACE

Sovol included a copy of OrcaSlicer, a free third-party slicer based on Open Source PrusaSlicer and BambuStudio. The software includes very good profiles for the SV06 ACE for PLA, PETG, TPU, and ABS. I didn’t test ABS, as that would require an enclosure, but it’s nice to know it's there.

I really enjoy seeing OrcaSlicer included with this 3D printer, as it’s one of the best, most cutting-edge slicers around. It can be somewhat intimidating for beginners, but when you turn off the advanced settings and let the default settings do the work, you’ll still get very nice prints.

Printing on the Sovol SV06 ACE

The Sovol SV06 comes with a sample coil of white PLA, which I didn’t bother using. If you want more colors and materials like silks and multicolor filaments, you should check out our guide to the best filaments for 3D printing for suggestions.

I did a speed test and printed a seriously decent Benchy in 13 minutes and 8 seconds. I used Speed Boat Rules (2 walls, 3 top and bottom layers, 10% infill, a .25 layer height, and .5 layer width). The layers are smooth along the upper hull and cabin, with just a tiny bit of slop in the prow, but there’s no ringing or layer shifts. This was printed in ordinary gray Inland PLA.

I printed a lot of dragons with the Sovol SV06 ACE for a Christmas Market, but you’re probably tired of seeing those. For PLA, let me show you a really cool Rustic Log Key Bowl by 3D Mieks. The bowl prints in two parts, an inner and an outer bowl, which allows you to make a more colorful print from a single-color machine like this one. I used Prusament Woodfill Linden Light for the inner bowl. This pale wood-filled filament uses clear PLA and scraps of wood waste from a lumber manufacturer. Prusa picked Linden because it is the national tree of their Czech homeland. The outer bowl uses Polymaker Gradient Wood, a dual-color filament that has no actual wood fiber. I used a fuzzy skin setting to make it a little more realistic.

It took 7 hours and 47 minutes to print both parts, using a .2 mm layer height and PLA default speed settings, with 200 mm/s on the outer wall and 270 mm/s on the inner. The bowl looks fantastic, with no stringing or bad layers.

For PETG, I experimented with a simple box I whipped up in Tinkercad with a bit of clip art sunk into the lid. The Sovol SV06 ACE printed this beautifully—I used all walls for a heavier, glass-like print. The lid was printed upside-down with no supports, with the bridging providing an interesting texture to the tree pattern.

The box printed in one hour, and the lid in 43 minutes, both using .2 layer height and default PETG settings. The slicer speed for PETG was throttled by a max flow rate of 12 ㎣/s The filament is Prusament Ultramarine Transparent PETG.

The ACE did a fair job with flexible filament, though there was a good deal of stringing. These tracks for my SMRFF Death Racer were printed in extra soft eSUN TPE, which only has a Shore Hardness of 83A. They look like shredded wheat on purpose: thanks to OrcaSlicer, I was able to apply a modifier block on one edge with “fuzzy skin” to give these tracks extra grip. These printed in one hour and 52 minutes, using a .28 layer height and OrcaSlicer’s default settings, which throttled the Max Volumetric speed to 3.6 ㎣/s.

Bottom Line

The Sovol SV06 ACE is a 3D printer with impressive features like 600mm/s top speeds, automatic bed leveling, dual Z-axis motors, vibration reduction, and a direct-drive extruder capable of printing at temperatures up to 300°C. I really appreciate that Sovol stuck with vanilla Klipper firmware and included OrcaSlicer – two Open Source programs that work well on their own, without causing user’s stress and headaches.

The monitoring camera and touch screen with a user-friendly interface prove that Sovol isn’t just copying their inspiration. They’re willing to expand on the design to give users a great printing experience.

Currently on sale for $269, the SV06 Ace is more than affordable. If you don’t mind the slower speed, you can still get the earlier Sovol SV06 for the bargain-basement price of $179. If you’re in the market for your first printer, another machine to look at is the Bambu Lab A1 Mini, our favorite pick for beginners who want a little color in their life. It’s $349 with a four color AMS unit.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She’s been a freelance newspaper reporter, online columnist and craft blogger with an eye for kid’s STEM activities. She got hooked on 3D printing after her son made a tiny Tinkercad Jeep for a school science project. Excited to learn more, she got a Creality CR10s and hasn’t looked back. She loves reviewing 3D printers because she can mix all her passions: printing, photography and writing. When she’s not modding her Ender 3 Pro or stirring glitter into a batch of resin, you’ll find her at the latest superhero movie with her husband and two sons.